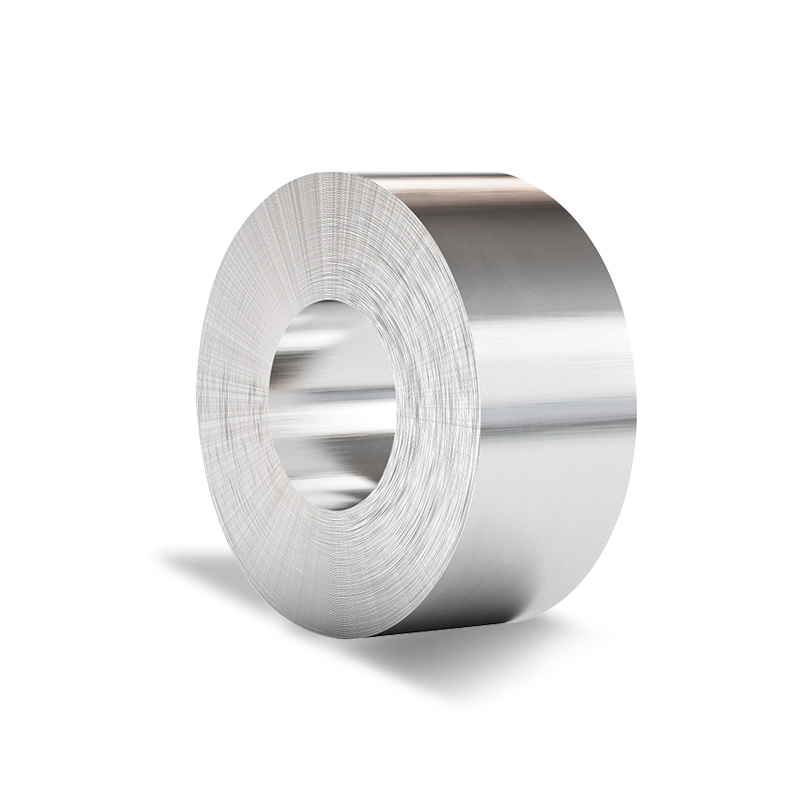

Product Description

Titanium Grade 9 Bar Description

Grade 9 titanium bar can maintain stable performance under high temperature and high pressure conditions, having remarkable strength and toughness. It is suitable for aerospace and aerospace engines and other fields. Besides, Grade 9 titanium bars can resist the erosion of corrosive media such as sea water and salt water, so they are widely used in marine engineering and chemical equipment. For another, Grade 9 titanium alloy has good weldability and is suitable for conventional welding, arc welding, laser welding and other processes. Lastly, Grade 9 titanium has a lower density and is lighter than many other metals, giving it an advantage in parts requiring lightweight designs. Grade 9 titanium bar is widely used in aerospace, marine engineering, chemical equipment and other fields.

Product Parameters

|

Product Name |

Titanium Grade 9 Bar |

|

|

Outer Diameter |

Round Bar |

4mm-500mm |

|

Hexagon Bar |

18mm-57mm (11/16″ to 2-3/4″) |

|

|

Square Bar |

18mm-47mm (11/16″ to 1-3/4″) |

|

|

Flat Steel |

1/2 "to 10", Thickness: 2mm-150mm, Can provide customized |

|

|

Length |

1-6 meters, Length can be customized |

|

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

|

Surface |

Black, Bright Polished, Rough Turning, Matt Surface Treatment, NO.4, BA, etc. |

|

|

Certificate |

ISO, SGS, BV |

|

|

Production Technology |

Hot Rolling, Cold Rolling |

|

Chemical Composition & Mechanical Properties

|

STM/ASME |

GB |

JIS |

Element Content(wt%) |

Mechanical Properties |

|||||||

|

N,max |

C,max |

H,max |

Fe,max |

O,max |

Others |

Strength Of Extension |

Ductility |

||||

|

Mpa,min |

%,min |

||||||||||

|

Pure Titanium |

Gr.1 |

TA1 |

Class1 |

0.03 |

0.08 |

0.015 |

0.2 |

0.18 |

- |

240 |

24 |

|

Gr.2 |

TA2 |

Class2 |

0.03 |

0.08 |

0.015 |

0.3 |

0.25 |

345 |

20 |

||

|

Gr.3 |

TA3 |

Class3 |

0.05 |

0.08 |

0.015 |

0.3 |

0.35 |

450 |

18 |

||

|

Gr.4 |

TA4 |

Class4 |

0.05 |

0.08 |

0.015 |

0.5 |

0.4 |

550 |

15 |

||

|

Titanium Alloy |

Gr.5 |

TC4 |

Class60 |

0.05 |

0.08 |

0.015 |

0.4 |

0.2 |

AI:5.5-6.75 |

895 |

10 |

|

Ti-6A1-4V |

V:3.5-4.5 |

||||||||||

|

Gr.7 |

TA9 |

Class12 |

0.03 |

0.08 |

0.015 |

0.3 |

0.25 |

Pd:0.12-0.25 |

345 |

20 |

|

|

Gr.9 |

TC2 |

Class61 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

AI:2.5-3.5 |

620 |

15 |

|

|

V:2.0-3.0 |

|||||||||||

|

Gr.11 |

TA9-1 |

Class11 |

0.03 |

0.08 |

0.015 |

0.2 |

0.18 |

Pd:0.12-0.25 |

240 |

24 |

|

|

Gr.23 |

TC4 ELI |

Class60E |

0.03 |

0.08 |

0.0125 |

0.25 |

0.13 |

AI:5.5-6.5 |

828 |

10 |

|

|

V:3.5-4.5 |

|||||||||||

Scope of Application

Used in aircraft turbines, engine components, aircraft structural components, aerospace fasteners, high-performance automation parts, marine applications, sports equipment, etc.

Factory

Factory

Factory

Factory

Shipping

Shipping Photos

Shipping Photos

Shipping Photos

Faq

Are you a manufacturer?

We are a manufacturer and trader in one.

Can we visit the factory?

Customers are welcome to visit the factory.

How are the goods purchased shipped?

Export standard packaging.

What is the delivery time?

Depending on the quantity purchased, the usual delivery time is 7-12 days.

Do we have access to samples? What are the costs?

Samples are supported, depending on stock availability a sample fee is charged, if a sample fee is charged we will refund the sample fee when the customer orders the main goods.

How do we get a quote for a product?

Please send me the name, size, quantity and packaging requirements of the product you wish to order and we will then provide you with the most accurate and favourable price.

Keywords

Titanium Grade 9 Bar

Contact Us

Classification