Categories

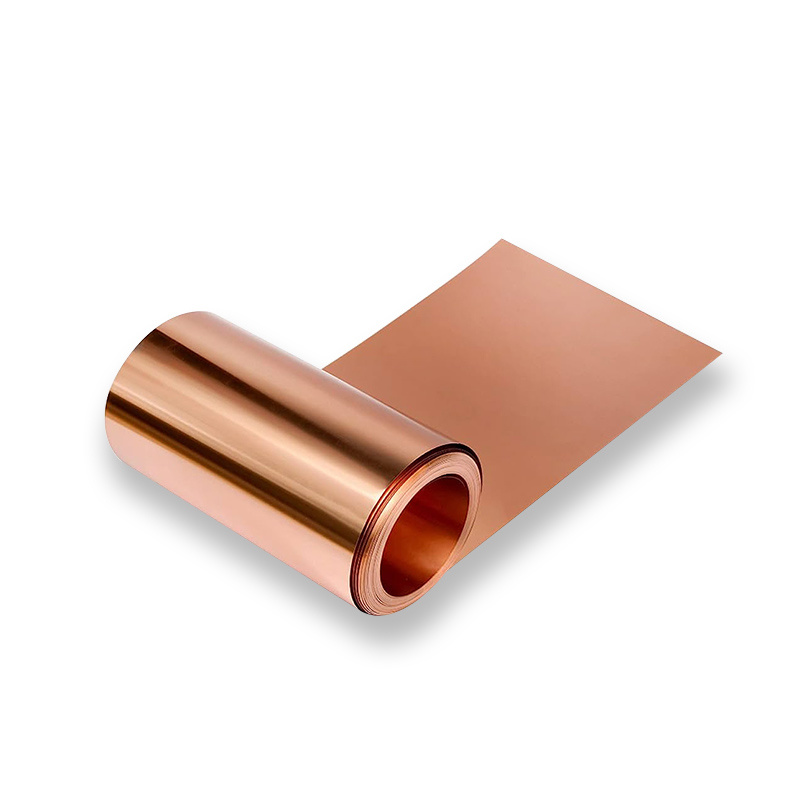

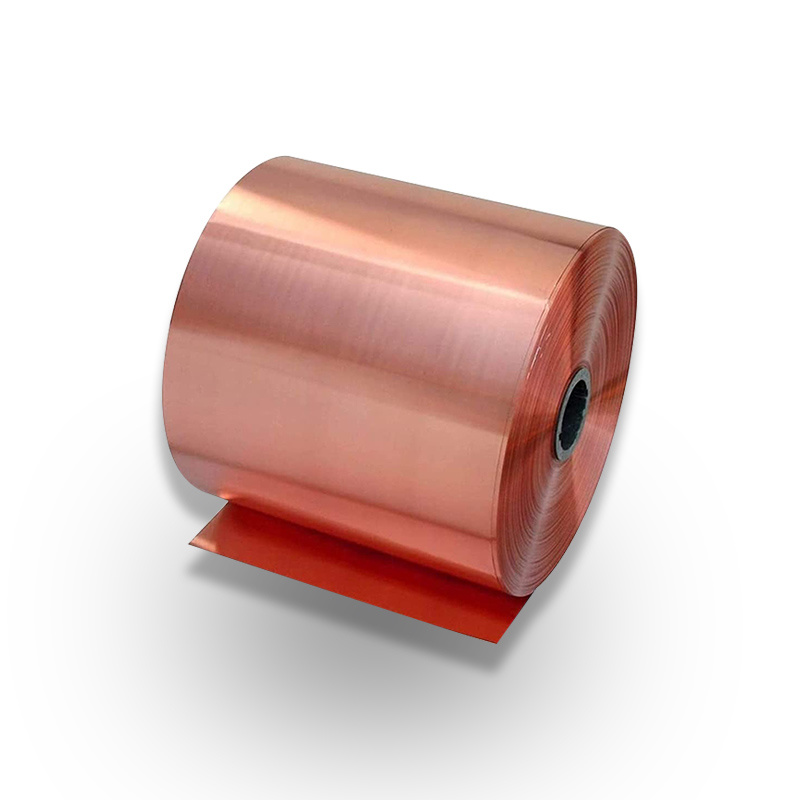

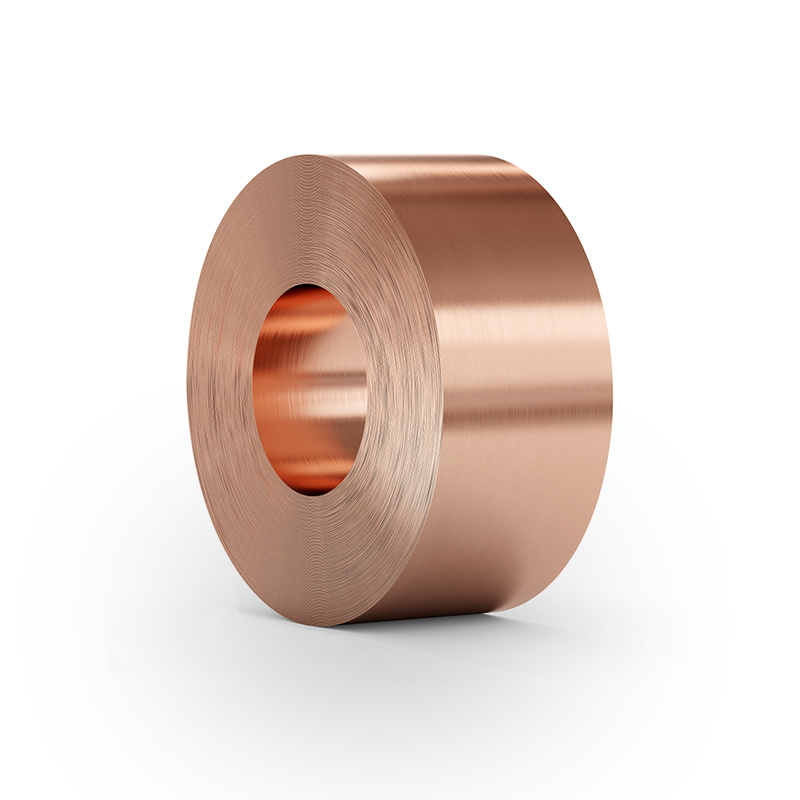

Copper Coil

C11000 copper coil is made from a copper-based alloy with extremely high purity, usually containing over 99.9% copper. This alloy has excellent electrical and thermal conductivity properties other than good corrosion resistance and mechanical strength.

C10200 copper coil is made from an extremely pure copper material known as oxygen free copper, with a purity of usually over 99.95%. Due to its extremely low oxygen content, C10200 copper coil has excellent electrical and thermal conductivity, as well as good welding and processability.

C10100 copper coil is made from an extremely pure copper alloy with a copper content of more than 99.99%, giving it excellent electrical and thermal conductivity. This high-purity copper is very popular in the electrical and electronic industries where high conductivity and good processability are required.

C12000 copper coil is made from a high-purity electrolytic copper, also known as ETP copper (Electrolytic Tough Pitch Copper). Its contains more than 99.9% copper, and small amounts of impurity elements such as oxygen, iron and sulfur.

C12000 welding performance and cold bending performance is good, generally no "hydrogen disease" tendency, can be processed in the reducing atmosphere, use, but not in the oxidizing atmosphere of processing, use, mainly to pipe applications, can also be plate, belt or bar, line supply. Used as gasoline or gas transmission pipe, drain pipe, condenser pipe, mine pipe, condenser, evaporator, heat exchanger, train parts.

C12200 coil is a high purity copper alloy, also known as EDM red copper, consisting mostly of copper and a small amount of phosphorus. C12200 coil is often used in electronic components, wire and cable, semiconductor equipment, chemical industry and other fields owing to good electrical conductivity, thermal conductivity and corrosion resistance.

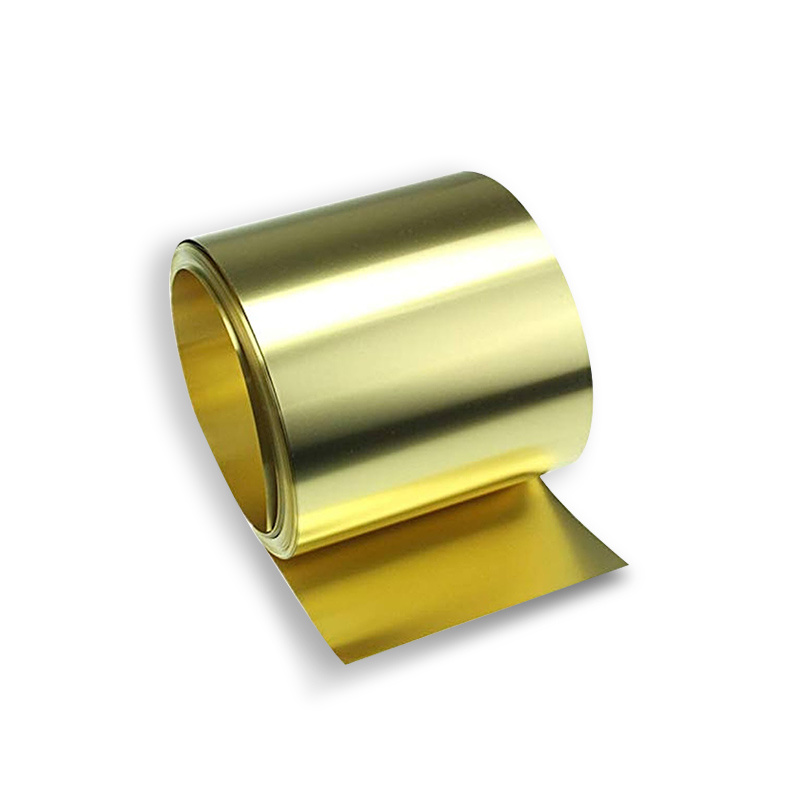

C21000 copper coil is made from a basic copper-zinc alloy containing approximately 95% copper and 5% zinc. Combining the good electrical and thermal conductivity of copper with the strength of zinc, it is a preferred material for many industrial applications. C21000 copper coil is widely used in various manufacturing fields due to its excellent plasticity, good processability and moderate strength.

C22000 copper coil is made from a copper consisting primarily of copper and zinc. This alloy is characterized by excellent electrical conductivity, corrosion resistance, plasticity and forming capabilities, making it a widely used material in construction, decoration and electrical fields.

C23000 copper coil contains about 85% copper and 15% zinc. It features good formability, corrosion resistance and high strength, and is adopted for a variety of applications. C23000 copper alloy is easy to process and can be manufactured by welding, brazing and bonding.

C24000 copper coil, commonly known as low-zinc brass, is an alloy with a copper content of approximately 80% to 90% and a zinc content of approximately 10% to 20%. This alloy is widely used in many fields owing to its excellent corrosion resistance, formability, and high strength and hardness.

C26000 copper coil is featured by excellent mechanical properties, processability and corrosion resistance, having a high copper content. It is widely used in aerospace, automobile manufacturing, shipbuilding and other fields.

C26200 copper coil is made from a structural copper-zinc alloy that can be strengthened by heat treatment. In addition to high strength and good elasticity, it has high copper content, excellent mechanical properties, processability and corrosion resistance, and is widely used in aerospace, automobile manufacturing, shipbuilding and other fields.

C26100 copper coil has high strength, good plasticity and corrosion resistance. It is very popular in a variety of applications, especially in the decorative and architectural fields.

C26800 copper coil is made from a copper-zinc alloy known for its electrical conductivity, thermal conductivity, ductility and corrosion resistance. It consists of 68% copper and 32% zinc, and is widely used in electrical, electronics, machinery, chemical industry, architecture, art and other fields.

C27400 copper coil is an alloy of high strength, good plasticity and excellent corrosion resistance. It is composed of mainly copper and zinc, in addition to trace amounts of lead, iron, and aluminum. The coil is widely adopted in electrical, decorative, automotive and construction fields and can be formed by cold and hot working.

C27000 copper coil is made from an alloy containing 65% copper and 35% zinc. It has excellent mechanical properties, corrosion resistance, formability and weldability, and is suitable for occasions requiring good cold working performance and high decorative properties.

C27200 copper coil is made from a high-quality copper material that is widely used in various fields. It is a high-purity copper combining zinc alloy with excellent electrical conductivity and corrosion resistance.

C28000 copper coil is made from a copper-zinc alloy containing 60% copper and 40% Zinc. Favored for good corrosion resistance, mechanical properties and formability, it is widely used in construction, marine, industry and other fields.