Categories

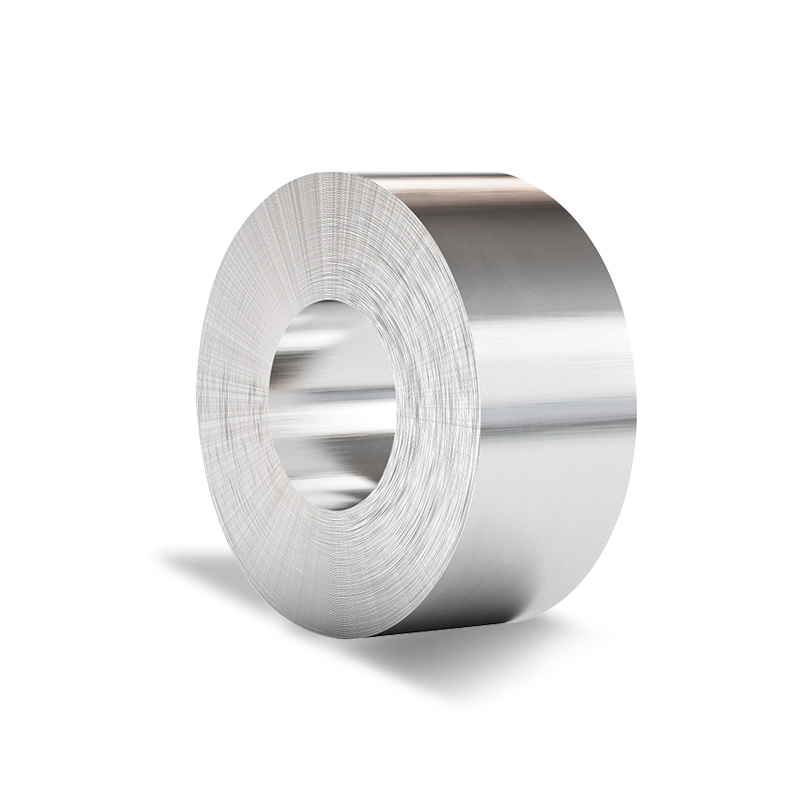

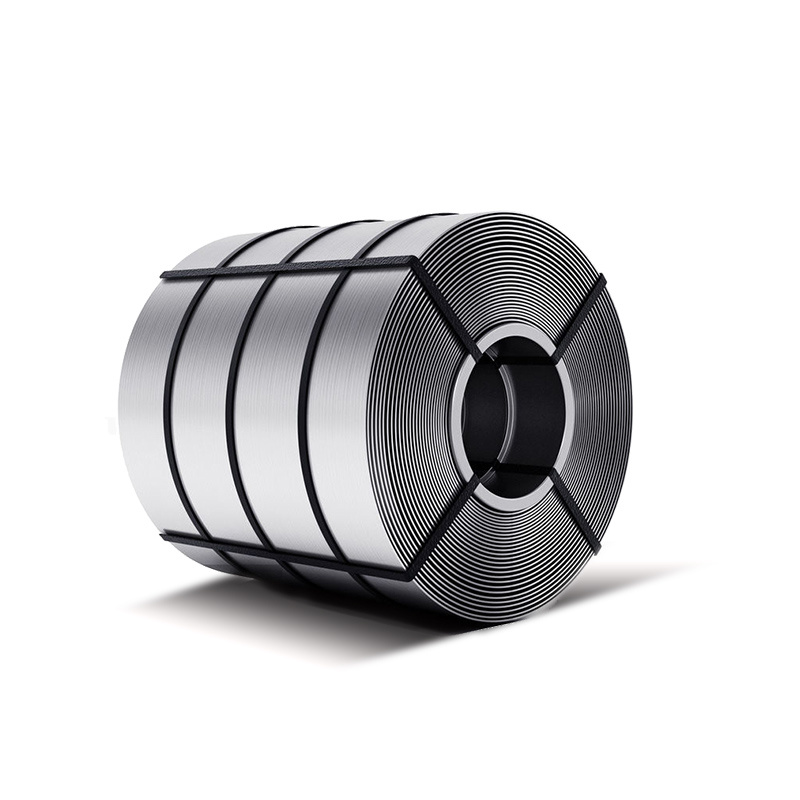

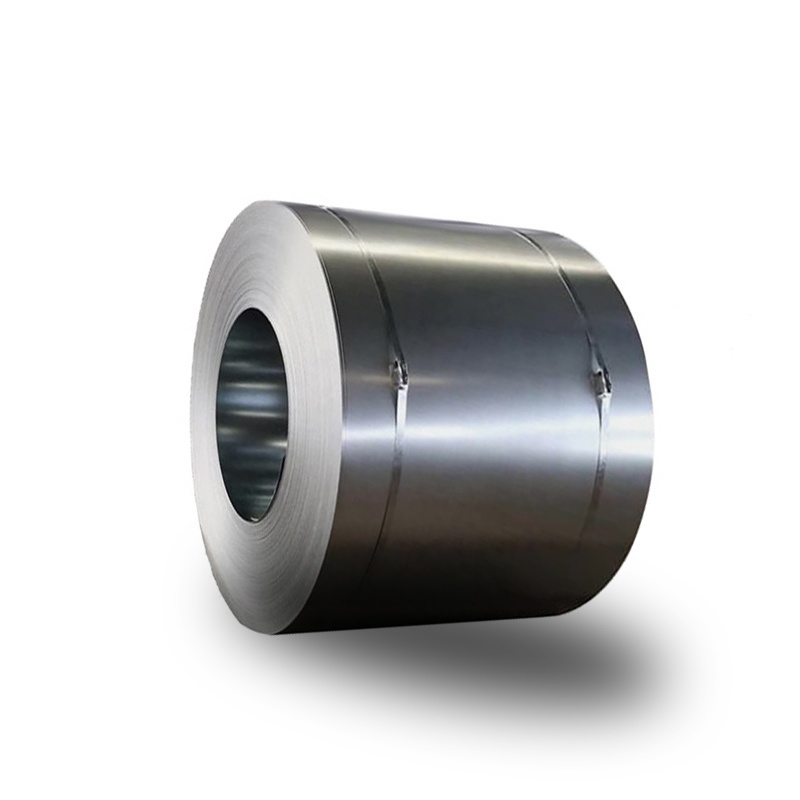

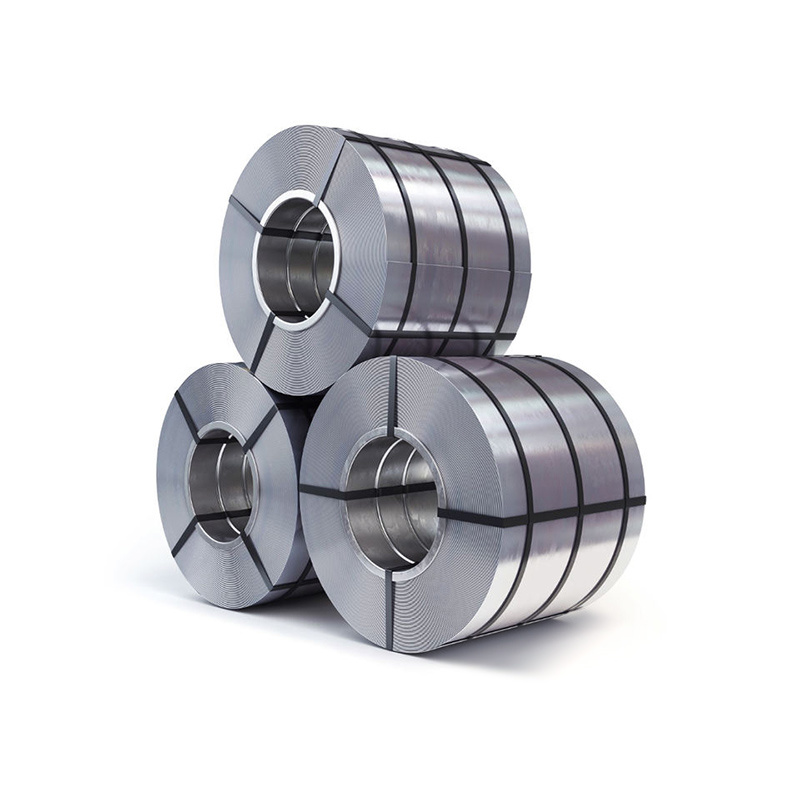

Stainless Steel Coil

304 stainless steel is a superior material with regard to corrosion resistance, heat resistance, low temperature strength and mechanical properties, as one of the most widely used types of stainless steel. In addition, it has exceptional hot-workability such as stamping and bending, without leaving heat treatment hardening phenomenon.

304L stainless steel is remarkably similar to 304 stainless steel in their chemical composition with one key difference. the maximum carbon of 304L stainless steel content is set at 0.08%, whereas grade 304L stainless steel has a maximum carbon content of 0.03%. This is why the “L” in 304L can be interpreted as extra-low carbon. It is widely used in the production of equipment and parts that demand better corrosion resistance and formability.

310S stainless steel is austenitic chromium-nickel stainless steel, with good oxidation resistance, corrosion resistance, because of a higher percentage of chromium and nickel, so that it has much better creep strength, with good high temperature resistance.

316 stainless steel also contains 2-3% molybdenum, in addition to iron, chromium and nickel. The addition of molybdenum significantly improves the performance of 316 stainless steel in certain corrosive environments, especially those containing chlorides. 316 stainless steel is more commonly used in situations requiring higher corrosion resistance.

316L stainless steel features a lower proportion of carbon in its composition. The amount of carbon cannot be higher 0.03%. This lowers the risk of carbon precipitation, making it a better option for welding to achieve maximum corrosion resistance.

316Ti is a titanium stabilized version of 316 molybdenum-containing austenitic stainless steel. It is more resistant to general corrosion and pitting/crevice corrosion than traditional chromium-nickel austenitic stainless steels such as 304.

309 stainless steel is a stainless steel material with excellent corrosion resistance and high temperature performance. It is commonly put into use in aviation, chemical industry, petroleum, food and other fields.

321 stainless steel is an austenitic stainless steel of excellent corrosion resistance at room temperature, as well as good high-temperature strength and creep resistance.

201 stainless steel is the steel that is resistant to the corrosion of weak media such as atmosphere, steam and water, while acid resistant steel refers to the steel that is resistant to the corrosion of chemical corrosive media such as acid, alkali and salt.

202 stainless steel is one of the 200 series of stainless steel, which is a stainless steel featuring low nickel content and high manganese content, because it is a stainless steel developed to save nickel, so its nickel content is relatively low.

302 stainless steel is an austenitic stainless steel containing 18% chromium and 8% nickel. Its chemical composition depends considerably on reasonable alloy design to achieve a series of excellent properties.

303 stainless steel is an austenitic, easy-cutting wear-resistant acid stainles steel containing sulfur and selenium respectively. It is used in situations where easy cutting and high surface finish are required.

301 stainless steel is an austenitic stainless steel with 17 percent chromium and 7 percent nickel, ensuring good strength and ductility when cold worked. Besides, it also has excellent corrosion resistance properties.

317L stainless steel is a lower carbon version of 317 stainless steel, which means it has better corrosion resistance and higher creep strength at high temperatures. It contains molybdenum, nickel and chromium as main alloying elements.

330 stainless steel is a high temperature alloy stainless steel, also known as Incoloy 330 or UNS N08330. It mainly consists of chromium, nickel, iron and other elements, and is characterized by exceptional high temperature resistance and corrosion resistance.

347 stainless steel is a high-temperature oxidation-resistant stainless steel material mainly composed of chromium, nickel and titanium. It is a stable material that can be used at high temperatures and can prevent corrosion and oxidation effectively.

305 stainless steel is a common austenitic stainless steel containing chromium, nickel, and manganese. Chromium can combine with oxygen to form a dense oxide film to protect materials from corrosion. Nickel can improve the material's heat resistance and toughness while reducing its magnetism. Manganese can increase the strength and hardness of materials.

403 stainless steel is a martensitic stainless steel with high chromium content and low carbon content. It is commonly used in applications requiring high strength and corrosion resistance.