Categories

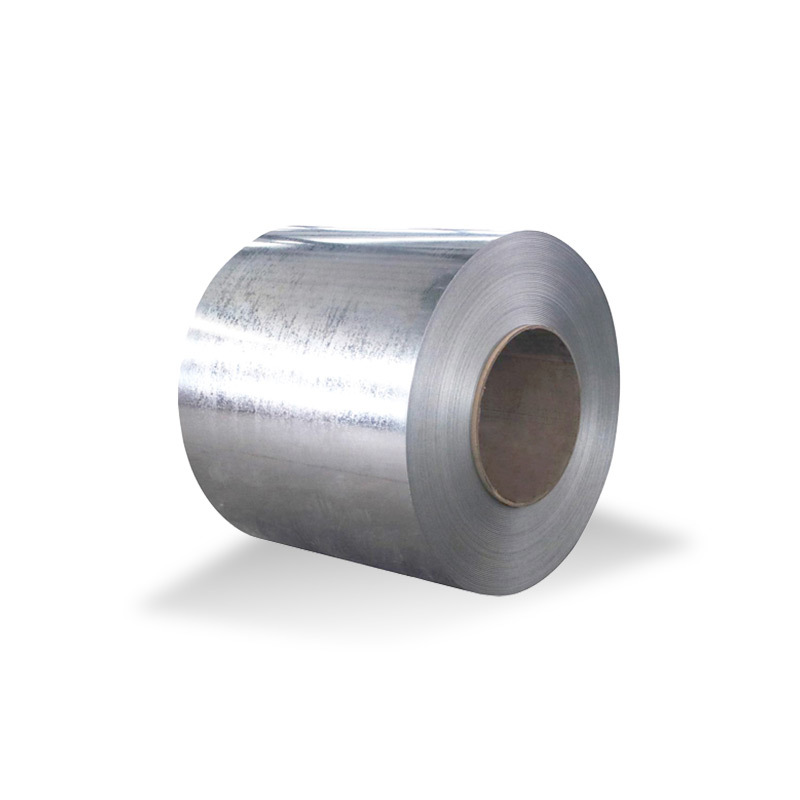

Galvalume Steel Coil

Galvalume steel coil is a type of steel that is coated with zinc for protection by an electroplating process. The galvanized layer is applied to cold rolled steel at low temperatures. So it is also known as cold galvanized steel.

Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating.

AZ stands for aluminum-zinc alloy, which is the material of the steel coating. AZ50 refers to the total weight of both sides of the aluminum-zinc alloy coating in the three-point test in ASTM a972 standard is 0.50 ounces/square foot, which is equivalent to 150 grams/square meter.

AZ55 is the standard for galvanized steel sheets and coils used in a variety of applications, including roofing and siding. The AZ55 name refers to the thickness of the coating on the coil, which is between 0.375 and 1.5mm (0.015 and 0.059 inches).

AZ150 galvalume steel coil has a coating thickness of 18 microns on one side and 36 microns on both sides. The coating alloy of the steel consists of 55% aluminium, 43.4% zinc and 1.6% silica. This coating of steel acts as a passive barrier to general corrosion. It also helps protect steel from trimmed edges and scratches.