Categories

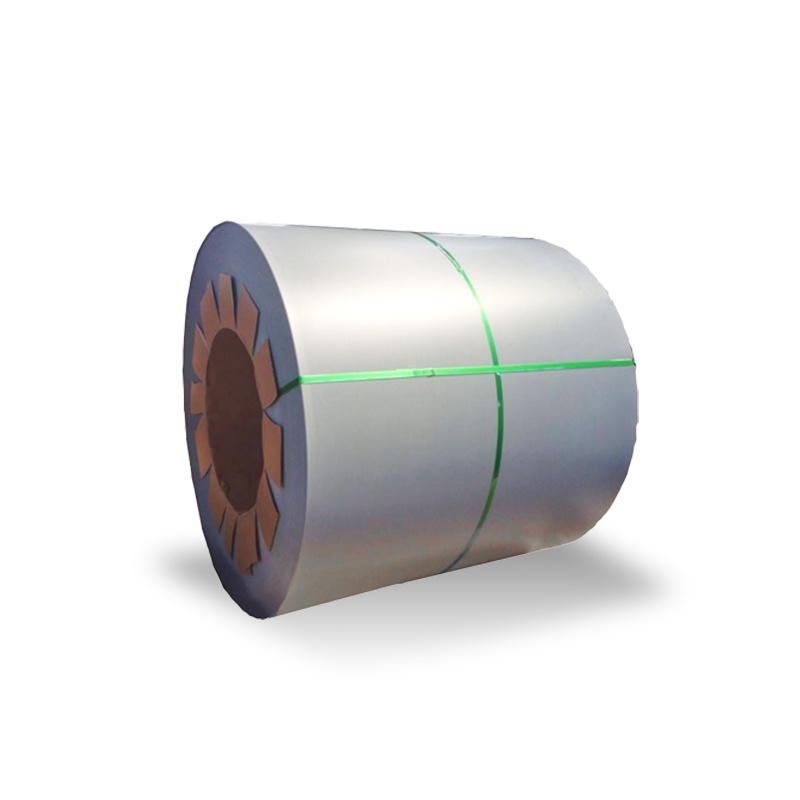

Tinplate Coil

Single Reduced Cold-Rolled Tinplate Coil

Single reduced cold-rolled tinplate coil refers to those steel coils where the steel substrate has been reduced to the desired thickness in a cold-reduction mill and subsequently annealed and temper rolled.

Double Reduced Cold-Rolled Tinplate Coil

Double reduced cold-rolled tinplate coil is given a partial cold reduction to reach an intermediate gauge, then annealed and given another cold reduction to the final gauge prior to coating with tin. The resulting product is stiffer, harder, and stronger than single reduced cold-rolled tinplate coil.

According to the difference of the tin plating thickness on the front and back of the thin steel coil, tinplate coil can be divided into two types: equal thickness tinplate coil and differential thickness tinplate coil. Among them, equal thickness tinplate coil refers to the same tin plating on the front and back of tinplate.

Differential Thickness Tinplate Coil

According to the difference of the tin plating thickness on the front and back of the thin steel plate, tinplate coil can be divided into two types: equal thickness tinplate coil and differential thickness tinplate coil. Among them, differential thickness tinplate coil refers to tinplate coil whose one surface carries a heavier coating than the other.

Tinplate coil is available in food grade and non-food grade. The main grades are MR and SPCC. The chemical composition requirements of MR materials are stricter than those of SPCC materials and have fewer impurities.

Chromium plated coil is also called tin-free steel coil, English abbreviation for TFS. It is a new type of can material developed for the situation of less metal tin resources and high cost.

Electrolytic Tinplate Coil (ETP)

Electrolytic tinplate coil is low-carbon mild steel sheet or coil coated on both surfaces with tin that is applied in continuous electrolytic operation. The surface of electrolytic tinplate coil is normally subjected to a passivation treatment and to oiling.