Categories

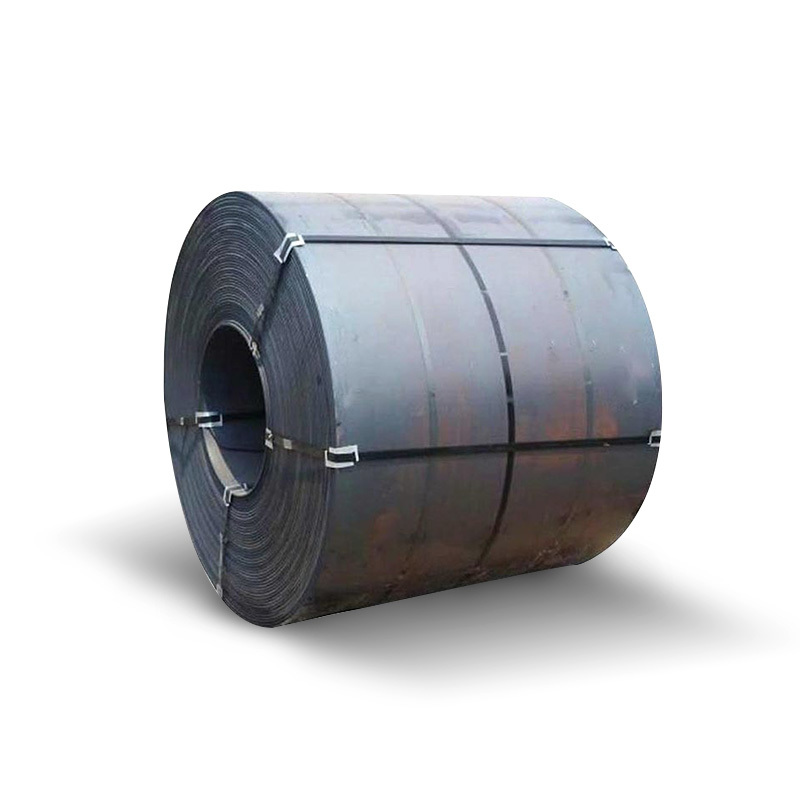

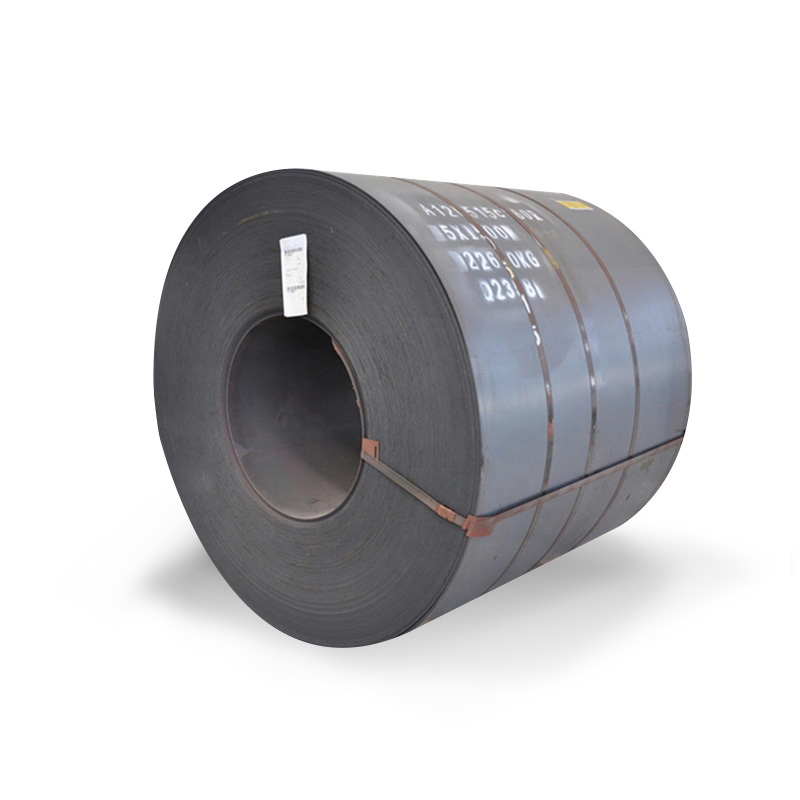

Carbon Steel Coil

A36/Q235/S235JR Carbon Steel Coil

A36 is a carbon structural steel coil whose chemical composition and mechanical properties strictly conform to American ASTM standards. Good mechanical properties, welding performance and corrosion resistance are basically why they are widely used in construction, bridges, machinery manufacturing and other fields.

A283/Q195 Cold Rolled Steel Coil

ASTM A283 cold rolled steel coil has low and medium tensile strength. The ASTM A283 steel specification covers four structural quality grades of mild steel, grades A, B, C, and D, for general application.

ASTM A514 steel is available in several grades. And they have the same mechanical properties. ASTM A514 steel coils are conventionally quenched and tempered steel with high yield strength, weldability and toughness. ASTM A514 steel is a special high-strength steel, mainly used as building structural steel.

A572 steel has four different grades: 42, 50, 60 and 65. Each of these grades differ in their mechanical properties and chemical composition.

SPCC/SGCC/SPCD/SPCE Cold Rolled Steel Coil

SPCC steel is produced by subjecting hot rolled steel to a cold rolling process, which not only improves its surface finish but also enhances its mechanical properties.

DC01/DC02/DC03/DC04/DC05/DC06 Cold Rolled Steel Coil

DC01, DC02, DC03, DC04, DC05, DC06 are steel grades of European standard DIN EN 10130, 10209 and DIN 1623, which are specified cold rolled steel. The grades are classified according to the maximum permissible yield strength.

DC01, DC02, DC03, DC04, DC05, DC06 are steel grades of European standard DIN EN 10130, 10209 and DIN 1623, which are specified cold rolled steel. The grades are classified according to the maximum permissible yield strength.

4135/4140/4142/6150 Alloy Coil EN10083-3

EN 10083-3 steel is an alloy steel used for quenching and tempering. This standard regulates the technical delivery conditions of alloy steels.

1008 carbon steel coil is primarily used in extruded, cold headed, cold upset, and cold pressed parts and forms. 1008 in the cold rolled condition is used for exposed or unexposed parts where bending, moderate drawing, forming and welding may be involved.

AISI 1018 carbon steel is a free machining grade that is the most commonly available grade around the world. Although its mechanical properties are not very unique, it still can be easily formed, machined, welded and fabricated.

1045 cold rolled steel coil is a medium carbon structural steel with good hot and cold workability and good mechanical properties. It is widely used in the industrial machinery manufacturing industry.

1023 cold rolled steel coil is made of low-carbon alloy steel designed for use in applications that require excellent machinability and formability. This type of steel comes with outstanding weldability and machinability, making it an ideal choice for various applications. Its composition mainly includes iron, carbon, and manganese. 1023 steel coil does not have strong heat resistance compared to other steels due to its low carbon content; therefore it should not be used for applications requiring high temperature operation unless proper heat treatments are applied beforehand such as tempering or annealing.

A573/A573M steel has grades including 58, 65 and 70. The coil is suitable for structural grade carbon-manganese-silicon steel in 3 tensile strength ranges. ASTM A573/A573M steel coils are mainly used to improve notch toughness at room temperature.

ASTM A588 steel is sorted into Class A, Class B, Class C, and Class K. The ASTM A588 steel specification is based on the standard specification for high-strength low-alloy structural steel with a lower yield point of up to 50ksi for applications requiring high strength and corrosion resistance.

A633 steel has four grades of A, C, D, and E. The thickness of grade C can reach 4 inches and the thickness of grade E can reach 6 inches. ASTM A633 steel specification is based on the standard specification for standardized high-strength low-alloy structural steel coil, which requires high notch toughness under low temperature conditions.

A656 steel coil is made of a high-strength low-alloy steel commonly used in structural applications where light weight and good formability are essential. A656 steel coils are manufactured in grades of 50, 60, 70 and 80 to meet the specified yield point.

A709/S355J0W Carbon Steel Coil

A709 steel coil is high-strength alloy steel coil that is widely used in construction, bridges, ships, automobiles and other fields. The chemical composition of A709 steel coil mainly includes carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel and other elements. The carbon content is relatively high, generally between 0.22%-0.29%.

EN10025-2 S235/S275/S355 Carbon Steel Coil

EN10025-2 steel coil is a low-alloy high-strength structural steel, which is made of carbon structural steel by adding a small amount of alloying elements.