Categories

Galvanized/PPGI/PPGL

Color Coated Galvanized Steel Sheet PPGI

Color-coated galvanized sheet PPGI uses hot-dip galvanized sheet, electro-galvanized sheet as the substrate. It is coated with one or more layers of liquid coating after surface pretreatment and roller coating method. After baking and cooling, the surface has good weather resistance, superior processing performance and is rich in colors.

Color Coated Galvalume Steel Sheet PPGL

Color-coated galvanized sheet PPGL uses hot-dip galvanized sheet, electro-galvanized sheet as the substrate. It is coated with one or more layers of liquid coating after surface pretreatment and roller coating method. After baking and cooling, the surface has good weather resistance, superior processing performance and is rich in colors.

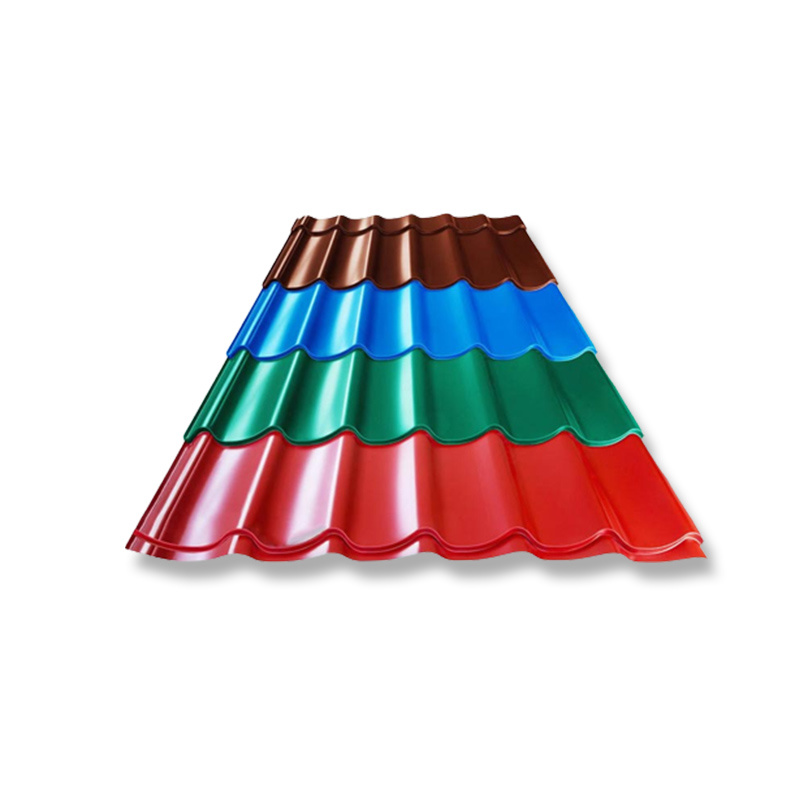

Corrugated color roof is a lightweight, strong, anti-corrosion building material. It is made of color-coated steel plate and designed in different styles, such as wavy, trapezoidal rib, tile, etc.

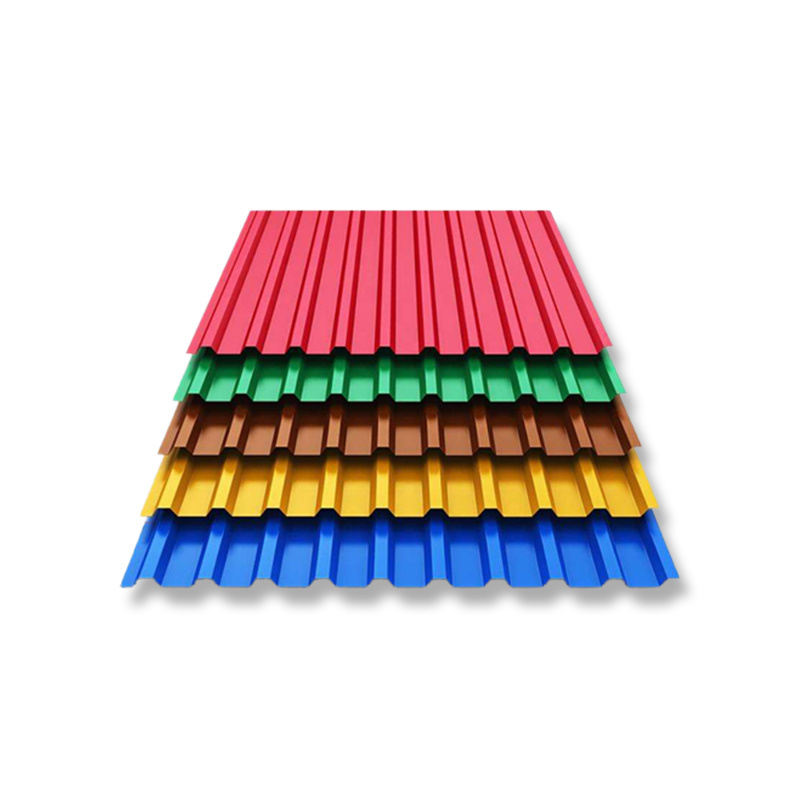

Color Coated Galvanized Roof Sheet PPGI

PPGI roof panels are beautiful and durable to meet your agricultural, residential and commercial needs. PPGI roof panels are available in a variety of different designs and sizes. Available thickness is 0.2 to 0.8mm, width is 600 to 1,250mm. In addition, colors and patterns are customizable.

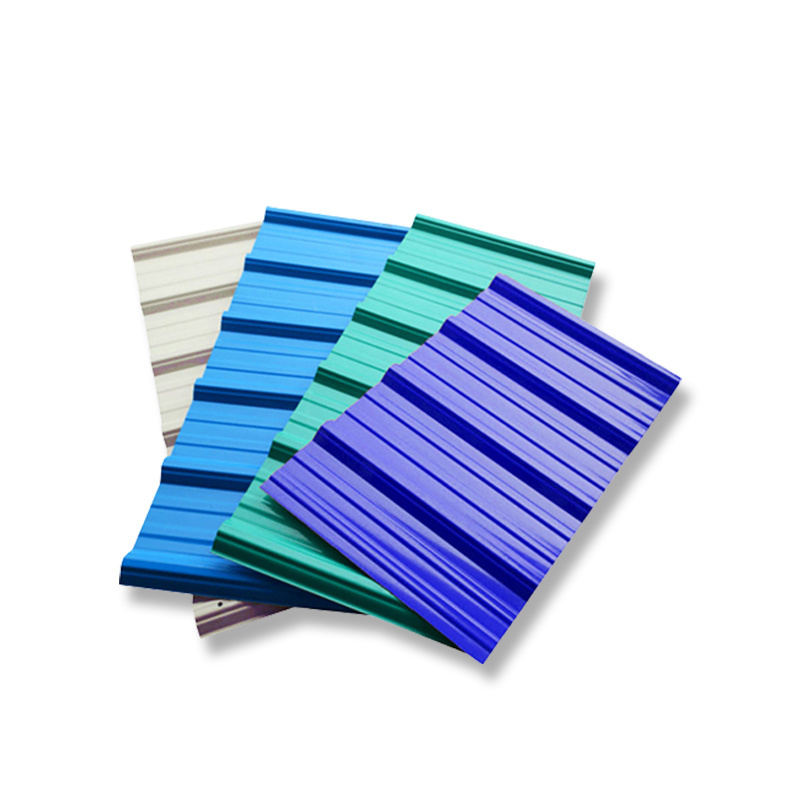

Color Coated Galvalume Roof Sheet PPGL

PPGL roof panels are an excellent building material. Its weight is only 1/30 of the traditional concrete roof, which is easy to install and greatly shortens the construction period. It also maintains the strength and durability of the steel, allowing it to last more than 25 years under normal conditions.

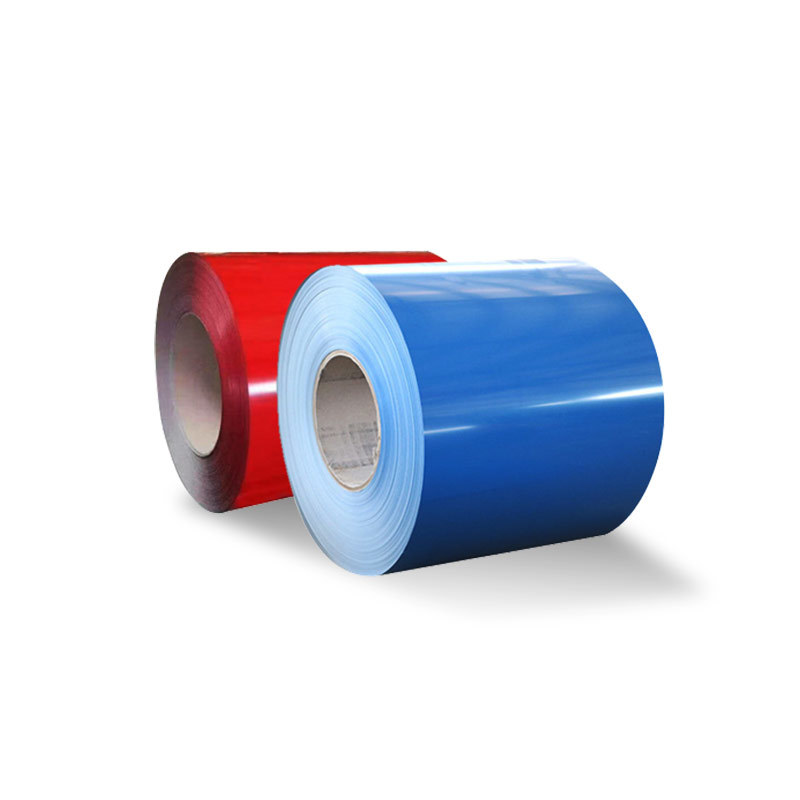

Color Coated Galvanized Steel Coil PPGI

PPGI coil is a popular material. It is based on hot-dip galvanized steel sheet or electro-galvanized steel sheet (galvanized layer) and is coated with multiple organic coatings to prevent it from rusting.

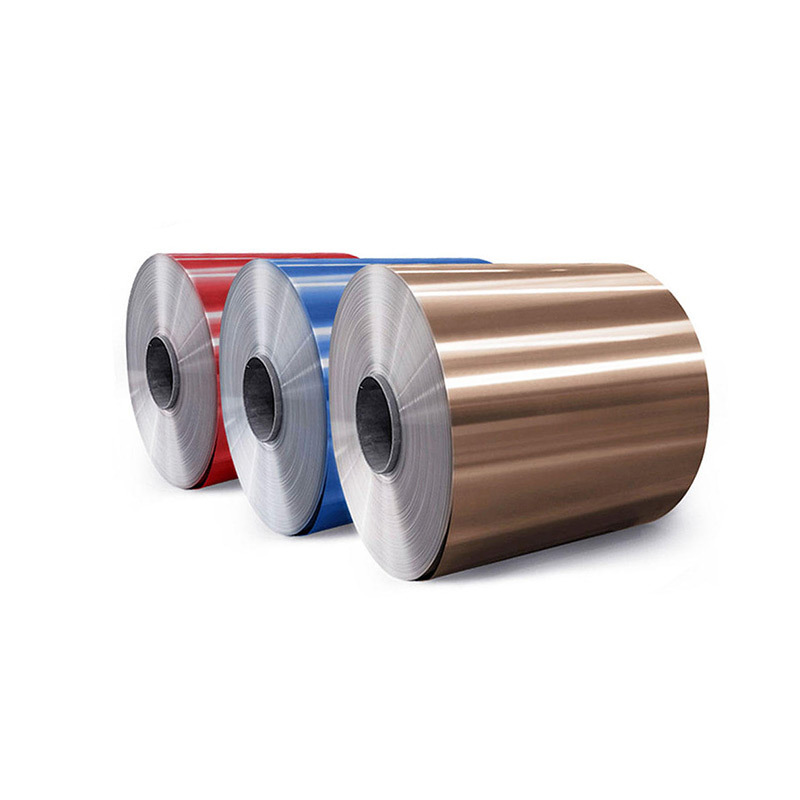

Color Coated Galvalume Steel Coil PPGL

Color-coated galvanized sheet PPGL uses hot-dip galvanized sheet, electro-galvanized sheet as the substrate. It is coated with one or more layers of liquid coating after surface pretreatment and roller coating method. After baking and cooling, the surface has good weather resistance, superior processing performance and is rich in colors.

Pattern Printing / Pattern Color Coating Coil

Patterned steel coil is a kind of color coated steel coil product with various patterns. Because of its beauty, convenience and excellent corrosion resistance, it has been widely used in home appliances, furniture, architectural decoration and other fields in recent years. The color and pattern can be customized.

Wood Grain Color Coated Roll Coil

Wood grain metal is one of the hot-selling pattern printed steel options. It combines the beauty of wood grain with the durability of metals such as steel and aluminum. Therefore, it is a popular material in wall panels, siding, fences, metal doors and other applications.

Color Coated Steel Coil for Household Appliances

The color coated steel coil for household appliances has good processing performance and decoration performance. It is widely used as the front panel, side panel, rear panel and inner panel of household appliances.

Galvalume steel sheet is a type of steel that is coated with zinc for protection by an electroplating process. The galvanized layer is applied to cold rolled steel at low temperatures. So it is also known as cold galvanized steel.

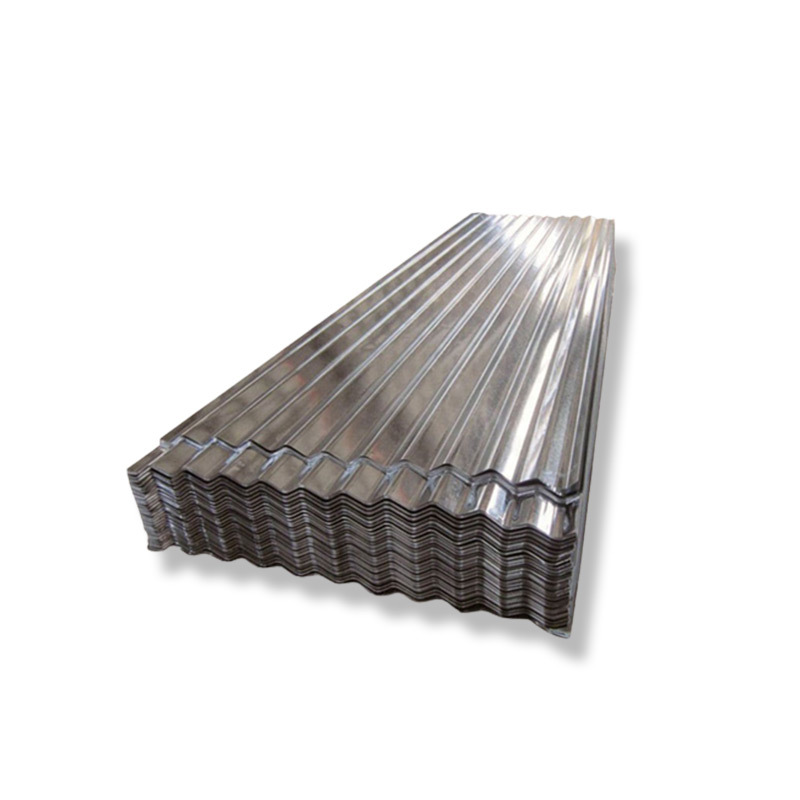

Galvalume Steel Corrugated Roof Sheet

Galvalume steel corrugated roof sheet is made of galvanized steel sheet used for roofing and coated with zinc. The zinc coating provides moisture and oxygen protection for the base steel. According to the galvanizing process, it can be divided into hot-dip galvanized steel plate and electro-galvanized steel plate. The corrugated design improves its strength and enable it to withstand harsh weather conditions.

Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating.

AZ stands for aluminum-zinc alloy, which is the material of the steel coating. AZ50 refers to the total weight of both sides of the aluminum-zinc alloy coating in the three-point test in ASTM a972 standard is 0.50 ounces/square foot, which is equivalent to 150 grams/square meter.

AZ55 is the standard for galvanized steel sheets and coils used in a variety of applications, including roofing and siding. The AZ55 name refers to the thickness of the coating on the steel plate, which is between 0.375 and 1.5mm (0.015 and 0.059 inches).

AZ150 galvalume steel sheet has a coating thickness of 18 microns on one side and 36 microns on both sides. The coating alloy of the steel consists of 55% aluminium, 43.4% zinc and 1.6% silica. This coating of steel acts as a passive barrier to general corrosion. It also helps protect steel from trimmed edges and scratches.

Galvalume steel coil is a type of steel that is coated with zinc for protection by an electroplating process. The galvanized layer is applied to cold rolled steel at low temperatures. So it is also known as cold galvanized steel.

Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating.