Product Description

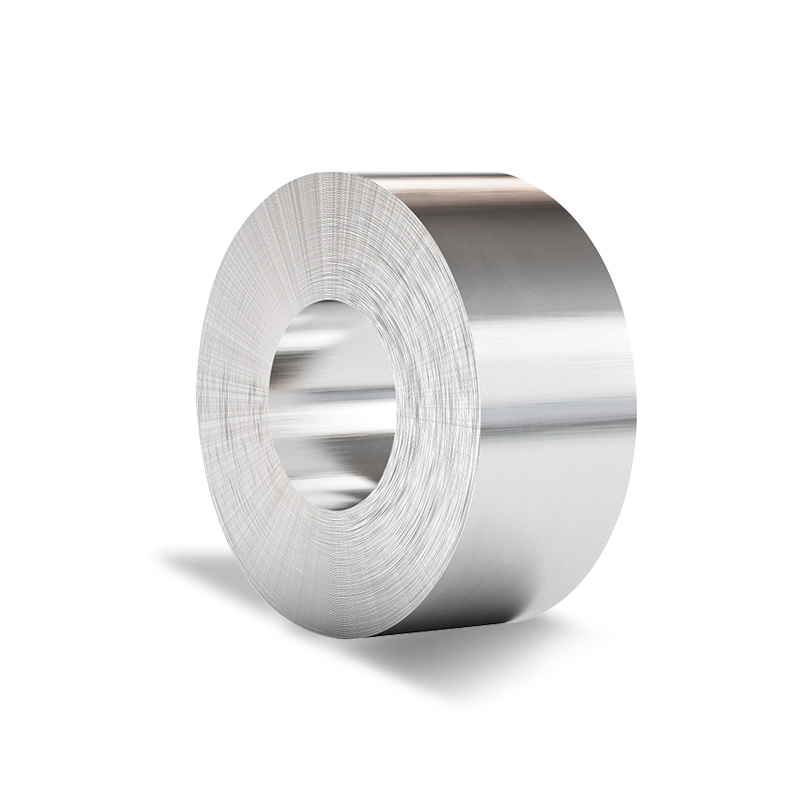

1100 Aluminum Coil Description

1100 aluminum coil has strong corrosion resistance and good plasticity. There are cold-rolled coil, hot-rolled coil, stretched coil and so on according to the different production process. Compared with 1060 aluminum coil, the strength of 1100 is slightly higher than that of 1060, so it is suitable for products with high strength requirements. However, since the aluminum content is not as high as that of 1060 aluminum coil, it is not recommended to use 1100 aluminum coil products in the heat dissipation and electrical conductivity industries. 1100 aluminum coil has good machining performance but lower cost. Therefore, 1100 aluminum coil has seen a gradual increase in usage in recent years, and it has become one of the most commonly used materials in the aluminum coil industry.

Product Parameters

|

Width |

20-3000mm or customized |

Thickness |

0.1-120mm or customized |

|

Length |

100-12000mm or customized |

Certificate |

ISO, SGS, BV |

|

Standard |

JIS, AISI, ASTM, GB, DIN, EN, etc. |

||

|

Brand |

1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 5A05 etc. 6000 Series: 6061 6063 6082 6A02 etc. 7000 Series: 7050 7475 7075 etc. 8000 Series: 8A06 8011 8090 etc. |

||

|

Surface |

Coating, Embossing, Drawing, Polishing, Anodizing, etc. |

||

|

OEM Service |

Punching, Cutting Special Size, Making Flat Surface, Surface Treatment, etc. |

||

|

Delivery Time |

Received 30% after deposit 7-15 working days |

||

|

Application |

Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware and other fields |

||

|

Sample |

Free Offers Sample |

||

|

Packaging |

Strapping, Plastic bag, Film, Wooden pallet standard seaworthy export packing or according to customer requirement |

||

Chemical Composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: Each |

Others: Total |

Al: Min. |

|

1050 |

0.25 |

0.40 |

0.05 |

0.05 |

0.05 |

- |

0.05 |

0.03 |

0.03 |

- |

99.50 |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

0.05 |

0.03 |

0.03 |

- |

99.60 |

|

1070 |

0.20 |

0.25 |

0.04 |

0.03 |

0.03 |

- |

0.04 |

0.03 |

0.05 |

- |

99.70 |

|

1100 |

0.95 Si Fee |

0.05~0.20 |

0.05 |

- |

- |

0.1 |

- |

0.05 |

0.15 |

99.0 |

|

|

2014 |

0.5~1.2 |

0.7 |

3.9~5.0 |

0.4~1.2 |

0.2~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

2017 |

0.2~0.8 |

0.7 |

3.5~4.5 |

0.4~1.0 |

0.4~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

91.5 - 95.5 |

|

2024 |

0.50 |

0.50 |

3.8~4.9 |

0.3~0.9 |

1.2~1.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

3003 |

0.60 |

0.70 |

0.05~0.20 |

1.0~1.5 |

- |

- |

0.10 |

- |

0.05 |

0.15 |

Allowance |

|

3A21 |

0.60 |

0.70 |

0.20 |

1.0-1.6 |

0.05 |

- |

0.15 |

0.1-0.2 |

- |

- |

Allowance |

|

3004 |

0.30 |

0.70 |

0.25 |

1.0~1.5 |

0.8~1.3 |

- |

0.25 |

- |

0.05 |

0.15 |

Allowance |

|

3005 |

0.60 |

0.70 |

0.30 |

1.0~1.5 |

0.2~0.6 |

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

Allowance |

|

3105 |

0.60 |

0.70 |

0.30 |

0.3~0.8 |

0.2~0.8 |

0.20 |

0.40 |

0.10 |

0.05 |

0.15 |

Allowance |

|

5005 |

0.30 |

0.70 |

0.20 |

0.20 |

0.5~1.1 |

0.1 |

0.25 |

- |

0.05 |

0.15 |

Allowance |

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

2.2~2.8 |

0.15~0.35 |

0.10 |

- |

0.05 |

0.15 |

Allowance |

|

5754 |

0.40 |

0.40 |

0.10 |

0.50 |

2.6~3.6 |

0.30 |

0.20 |

0.15 |

0.05 |

0.15 |

Allowance |

|

5A05 |

0.50 |

0.50 |

0.10 |

0.3-0.6 |

4.8-5.5 |

- |

0.20 |

- |

0.05 |

0.05 |

Allowance |

|

5083 |

0.40 |

0.40 |

0.10 |

0.4~1.0 |

4.0~4.9 |

0.05~0.25 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

6061 |

0.40~0.8 |

0.70 |

0.15~0.4 |

0.15 |

0.8~1.2 |

0.04~0.35 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

6082 |

0.70~1.3 |

0.50 |

0.10 |

0.4~1.0 |

0.6~1.2 |

0.25 |

0.20 |

0.10 |

0.05 |

0.15 |

Allowance |

|

7075 |

0.40 |

0.50 |

1.2~2.0 |

0.30 |

2.1~2.9 |

0.18~0.28 |

5.1~6.1 |

0.20 |

0.05 |

0.15 |

Allowance |

Mechanical properties

|

Tensile Strength (MPa) |

Yield strength (MPa) |

Hardness HB |

Elongation Rate (%) |

|

89.6 |

34 |

23 |

15-28 |

Physical Performance

|

Density |

Melting Point |

Modulus of Elasticity |

Thermal Conductivity |

|

2.71 Kg/m³ |

643-675.2 °C |

68.9 GPa |

222W/m.K |

Annealing State

|

Brand |

Annealing State |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Scope of Application

|

Aluminum Uses And Application Area |

|

|

Food Packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Building |

Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

|

Transportation |

Auto parts, passenger car bodies, aviation ships and air cargo containers. |

|

Electronic Equipment |

Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

|

Consumer Goods |

Umbrellas, cooking utensils, sports equipment, etc |

|

Other |

Military, color coated aluminum plate |

Factory

Factory

Factory

Factory

Shipping

Shipping Photos

Shipping Photos

Shipping Photos

Faq

Are you a manufacturer?

We are a manufacturer and trader in one.

Can we visit the factory?

Customers are welcome to visit the factory.

How are the goods purchased shipped?

Export standard packaging.

What is the delivery time?

Depending on the quantity purchased, the usual delivery time is 7-12 days.

Do we have access to samples? What are the costs?

Samples are supported, depending on stock availability a sample fee is charged, if a sample fee is charged we will refund the sample fee when the customer orders the main goods.

How do we get a quote for a product?

Please send me the name, size, quantity and packaging requirements of the product you wish to order and we will then provide you with the most accurate and favourable price.

Keywords

1100 Aluminum Coil

Contact Us

Classification