Product Description

Double-End Studs Description

Double End Stud are used in all types of applications. They can be welded to a flat surface, or to the inside or outside of an angle. The materials used are mild steel, stainless steel, alloy steel and copper. It is used almost in every industry mnufactured according to the latest standard such as IS/ANSI/ASME/DIN.

The Double end stud is threaded on both sides of the bolt and should be used when the exact length of thread is known for the application. The stud can be custom-made to fulfill individual necessities. Most recent machines and propelled innovation are utilized in the assembling procedure by our master experts.

Product Parameters

| Types Of Studs | |

|

|

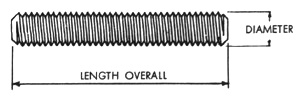

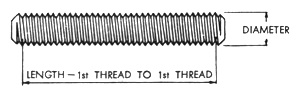

| Type 1 | Type 2 |

| General purpose. The length of this type is measured from end to end. Threads are UNRC-2A. |

Studs for temperature-pressure piping. These studs are made to the dimensional standard requirements of ANS B16.5 and have a length measurement requirement different from all other studs, i.e., the length is measured from first thread to first thread, exclusive points. Points are flat and chamfered. Threads are UNRC-2A for all sizes 1 in. and under and 8UNR-2A for all sizes over 1 in. |

|

|

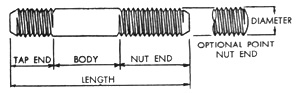

| Tap-end Studs | Double-end Studs |

| Tap-end studs have a short thread on one end, called the tap end which is threaded to a Class NC5 or Class UNRC-3A fit. This end is for screwing into a tapped hole. The other or nut end is threaded with a Class UNRC-2A fit. Length of the stud is measured overall. The tap end has a chamfered point, but the nut end may have either a chamfered or round point, at the manufacturer’s option. Tap-end studs are available in four types, as follows: Type 1 – Unfinished, have a full diameter but no standard body tolerances. Type 2 – Finished, having either an undersize body with rolled threads or a full-size body with cut threads, at the manufacturer’s option. The body portion will be finished to a maximum Class 2A pitch diameter or maximum basic major diameter of the nut-end thread. Type 3 – Finished, full-body, having tolerances equal to that on major diameter of Class 2A threads. Type 4 – Finished close-body, milled or ground to tolerances specified by the user. |

Double-end studs have equal-length threads on each end to accommodate a nut and are threaded to a Class 2A fit. Length of stud is measured overall. Both ends have chamfered points, but round points may be furnished on either or both ends at the manufacturer’s option, This style is furnished in the same four types listed for tap-end studs. Double-end studs are used for flange bolting or other applications where torching from both ends is necessary or desirable.Most steel grades not heat treated or quenched and tempered can be furnished on special order for production quantities. Only the Type 2 continuous thread studs made to specification ASTM A193 grade B7 are stocked in a full range of sizes. |

Factory

Factory

Factory

Factory

Shipping

Shipping Photos

Shipping Photos

Shipping Photos

Faq

Are you a manufacturer?

We are a manufacturer and trader in one.

Can we visit the factory?

Customers are welcome to visit the factory.

How are the goods purchased shipped?

Export standard packaging.

What is the delivery time?

Depending on the quantity purchased, the usual delivery time is 7-12 days.

Do we have access to samples? What are the costs?

Samples are supported, depending on stock availability a sample fee is charged, if a sample fee is charged we will refund the sample fee when the customer orders the main goods.

How do we get a quote for a product?

Please send me the name, size, quantity and packaging requirements of the product you wish to order and we will then provide you with the most accurate and favourable price.

Keywords

Double-End Studs

Contact Us

Classification